Empower | Collaborate | Innovate

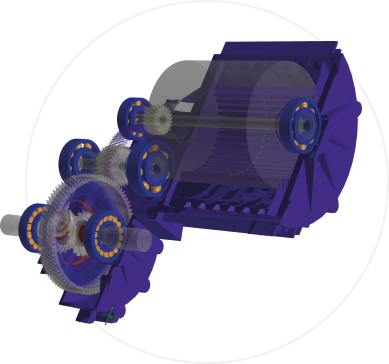

我们把行业领先的、获奖无数的机电一体仿真软件进行重组,提高仿真效率并优化工作流程

我们所构建的云端应用生态系统与您的传动系统开发周期完美匹配,从快速建模及概念探索,再到详细仿真,以及虚拟产品的签发,

Romax Nexus数字化平台可智能集成更广泛的CAE工具链,助力您的团队实现“首次即正确”的设计。

Romax Nexus平台柔性化的配置方式:灵活选用,自由组合,按需定制

The Romax flexible product suite

Trusted & validated

Trusted proprietary technology: parametric full system definition and intelligent combination of analytical, empirical and finite element methods

CAE-led design

Combine easily editable models with upfront, repeatable, multi-fidelity analyses and multi-attribute optimisation to make smarter engineering decisions and reduce risk of innovation

Process improvement

Flexible product suite which promotes collaboration and efficient working, including optimisation and process automation, to boost productivity

Fast

Build and analyse models in minutes, and use rapid, actionable results to understand the effect of design changes, ask ‘what if’ questions and get instant engineering insight

Virtual prototyping

Rely on trustworthy simulation to reduce physical prototyping, shorten development times and reduce costs

Partner ecosystem

The heart of a unique partner ecosystem for integrated powertrain design, to break down barriers within and across organisations through CAE integration

“Combining proven software and engineering expertise from Romax gave us the confidence to take the risk of eliminating a full prototype iteration, relying heavily on virtual simulation. With this new approach, we have achieved a 7 to 9 month reduction in development time.”

Valeo

“The way Romax software integrates with other software packages also saves us time. Its ability to provide interfaces and to share results for interpretation by our engineers is another reason we use it internationally.”

GKN Driveline

“Most importantly, the software is accessible and easy to use – it gives us a streamlined and integrated process which saves time in model building and reduces the chance of errors in data re-entry.”

Tumosan

“Using Romax products the speed from design to evaluation is so fast that experimental results can be obtained to validate numerical analysis results, and as a result there is almost no need for additional CAE.”

Daihatsu

Supercharge your capabilities:

欢迎进入一个全新的工作方式