12/07/2021

Romax are pleased to announce the 2021 release of the complete Romax software suite: Concept, Enduro, Spectrum, Energy, Spin and Evolve. The release sees new features across the simulation portfolio, with a particular focus on enabling our customers to democratize advanced technologies and to work in more collaborative ways.

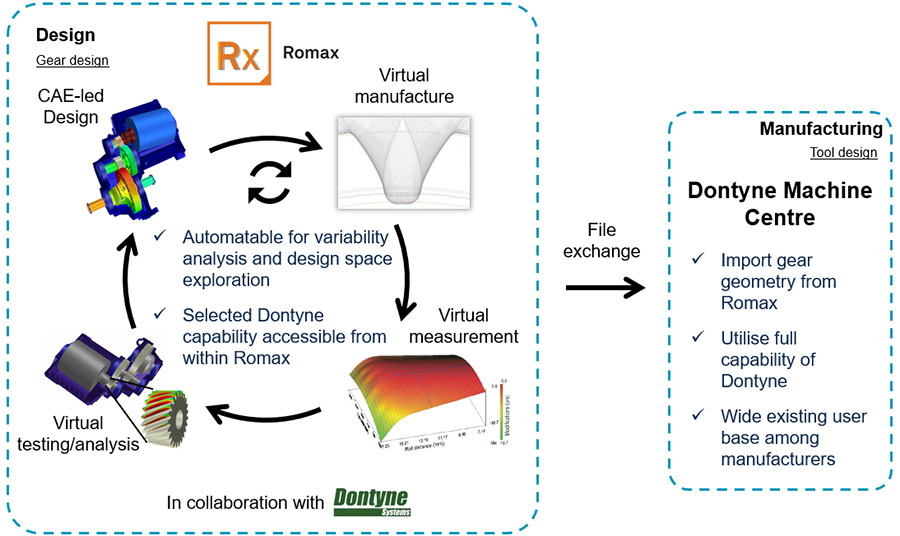

Virtual Gear Manufacturing with Dontyne

Closing the loop on gear simulation and manufacturing

Even though their roles greatly impact each other, existing gear design processes often mean disconnects between the gear manufacturer and the gear designer. The gear designer might decide on a design that performs well in simulation but cannot be manufactured to the required specification. This may mean the gear design is changed during production, which can lead to long delays and high cost, as well as differences in the expected performance for NVH, durability and efficiency.

With this new technology, we have embedded Dontyne’s gear manufacturing simulation capability into Romax Enduro’s gear design and analysis tools meaning that gear design, analysis and manufacturing can be considered virtually for the first time. This leads to reduced development costs, shorter time to market, and greater confidence in the manufactured product.

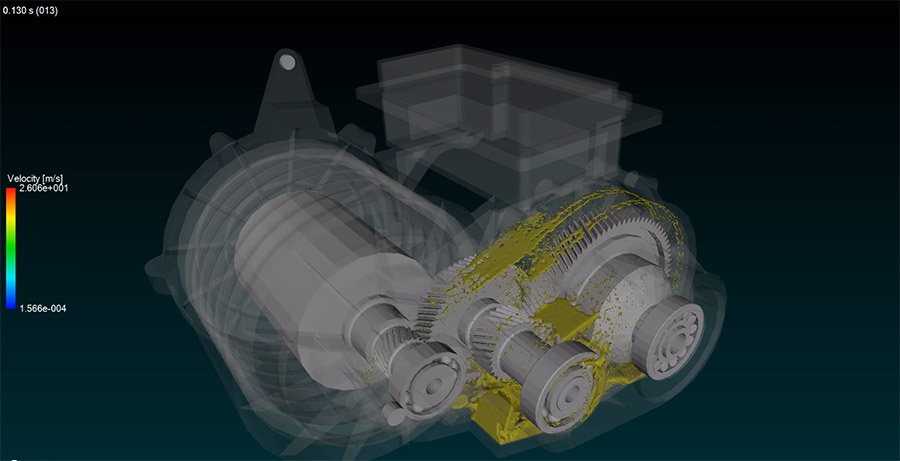

Lubrication simulation with Particleworks

Democratising CFD analysis

Lubricant distribution predictions and churning loss simulations are typically not an early part of a transmission design process. This is because CFD analysis requires significant modelling and simulation time along with high levels of expertise, so is typically done when the design is finalised, or when a prototype has been manufactured. This means that problems are typically found late in the design and development process, when it is much more expensive to resolve issues.

In the 2021 release, we have developed a new interface between Romax Energy and Particleworks, to enable CFD analysis to be performed as soon as you have a Romax Energy model, early in the design process. This is true “CAE-led design”, enabling transmission engineers and non-CFD specialists to conduct informative CFD simulations to gain insight into lubricant distribution within the transmission and understand the effect on churning losses, allowing them to optimise for efficiency, improve product quality and reduce time to market.

Join our upcoming webinar to find out more.

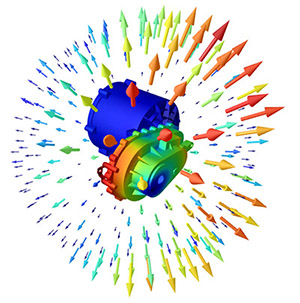

In-vehicle NVH simulation with VI-grade

Virtually test drive your powertrain designs in real-time for in-vehicle sound quality assessment

Engineers are always seeking to improve product quality, with NVH, in particular, being a key differentiator in a crowded market. To do this, engineers need to understand how the powertrain noise will sound in the vehicle cabin before it is manufactured. Additionally, there are challenging drives to reduce prototyping and testing cycles, again demanding better understanding of product performance. In 2021, we have expanded our interface with VI-grade’s technology, to allow our users to apply a CAE-led design approach to the world of vehicle NVH testing. Romax Spectrum’s accurate prediction of gearbox and electric powertrain noise and vibration can now be automatically calculated and exported for use in the VI-grade NVH simulator, which uses a mix of test and simulation data to provide a virtual driving experience that accurately represents in-vehicle noise from all sources. By presenting complex CAE simulation results in a way that anyone can interpret and understand, this feature will democratize advanced technologies and aid with cross-departmental collaboration.

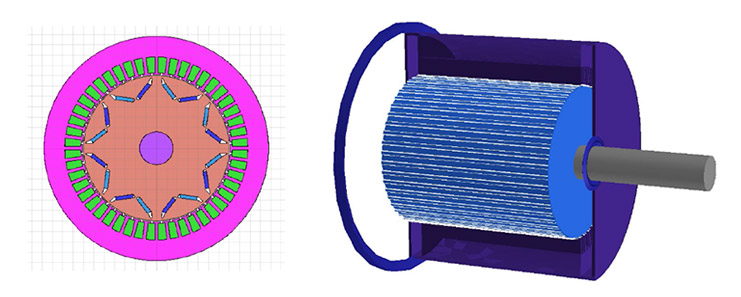

Interface with JMAG-Express

Integrating mechanical and electromagnetic solutions

Romax has been rapidly building on capabilities for electromechanical solutions for the last 15 years. Whilst processes are much improved, engineers still need better ways to understand the mechanical performance of electric motor early in the development process, with access to multi-fidelity simulation tools. Romax Evolve provides such a multi-fidelity environment for mechanical simulation of electric machine durability, NVH and efficiency, whilst Romax Concept is a fast simulation tool for early stage development of the complete electric drivetrain. Both tools have now gained an interface to JMAG Express, a concept-level online parametric design tool for motor electromagnetic performance. Linking these tools together provides a fast, easy workflow at the concept and sizing development stage when design iterations need to be at their most efficient. This provides an enhanced workflow integration for motor designers looking to understand motor and electric powertrain efficiency performance right from the start.

Further enhancements include:

- Inclusion of motor efficiency maps, to calculate overall energy loss for an electrified driveline

- Show velocity on housing in Acoustic Analysis– to see the local structural deformations at the same time as the acoustic results and use this to interpret the source of any directional noise

- Vehicle performance and efficiency predictions on electric powertrain designs using vehicle, transmission and electric machine data in Romax Concept

- FE speed improvementsfor a significant decrease in model preparation and solve times

- SKF bearing calculations from SKF’s cloud calculation service embedded into Romax software

- Hybrid bearings, with steel rings and ceramic rolling elements

- Import REXS files, a standardised file format for exchange of geared system CAE models

- Electric machine NVH workflow enhancements, including for skew and eccentric rotors

- Improvements to batch running and parametric study to enable more optimisation and sensitivity studies

To learn more about our new features, download our flyer and register for our upcoming webinars. Users with a support account can also view an on-demand webinar showing all the key features in this release. For further information, do not hesitate to get in touch with your account manager.